There is an eternal debate among those of us who wield the iron, as to what the best way to go about desoldering components is. For surface mount components, I’d dare to say it’s a mostly settled question (I tread here at my own peril) with hot air rework stations being excellent and reasonably functional low cost units from china being widely available. I myself have one of these, which works reasonably well.

Figure 1: Sparkfun hot air rework station.

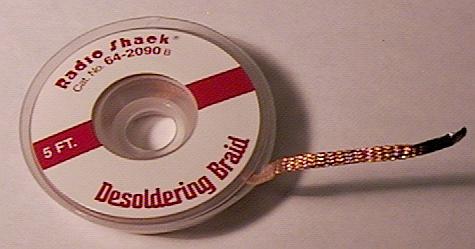

But when it comes to through hole components, the debate is much more raucous. Many people swear by application of their main iron and plain old solder wick. This was the first way to remove a soldered component that I was personally introduced to, and still find it a valuable tool in my kit.

Figure 2: Solder wick.

Others use so called “solder suckers” – either of the spring or bulb type.

Figure 3: Spring type solder sucker.

Figure 4: Bulb type solder sucker.

Personally, I’ve tried to use these on and off for years in a pinch in other people’s labs, and I have found them worse than garbage. I’ve never once successfully removed a component using one, but the heat I had to apply to try and keep the solder molten long enough to move the sucker in place has ruined many parts and pads under my watch. Never mind the awkwardness of tying to wrangle the component, sucker, and iron all at the same time.

I still remember the first time I was introduced to the “professional” solution to this problem. I was an undergraduate and I had soldered down some 16 pin dip that needed to be removed. The TA suggested I go ask the lab technician for use of his desoldering station, which was a concept I had not, to that point, considered.

Figure 5: Professional Weller desoldering station.

I still remember the sense of awe I had when I touched the iron to a pin, tapped a button, and the pin was clean. Voila!

Since then, I have been lucky enough to usually have access to them when I need them in professional environments, and I still aspire to own one someday – some day that I find one dirt cheap as surplus. But until then, I’ve found a pretty good alternative.

About ten years ago at Radio Shack, I found a bulb type desoldering iron, for about $17. I picked it up, skeptical, and brought it home. The next time I needed to remove a component, I plugged in this scraggly little iron. No temperature control and a rubber bulb. I was sure it would be garbage.

Figure 6: Bulb type desoldering iron.

But no, almost as easily as the professional irons, the bulb type iron took two passes to remove all the solder from a pin, but it worked. And more importantly, it worked without lifting a pad or driving a component to thermal death.

Figure 7: Vacuum tip.

Since then, it has been my go-to home solution for desoldering, and honestly, I’ve felt no severe need to shell out the cash for a professional Weller desoldering station.

In ten years since I got it, the price seems to have gone up by $6, but what appears to be the identical iron is still available at amazon (don’t worry, it’s not a referral link). Who knows, maybe the odd, still open Radio Shack even stocks them.